MOIK project

Project at a glance

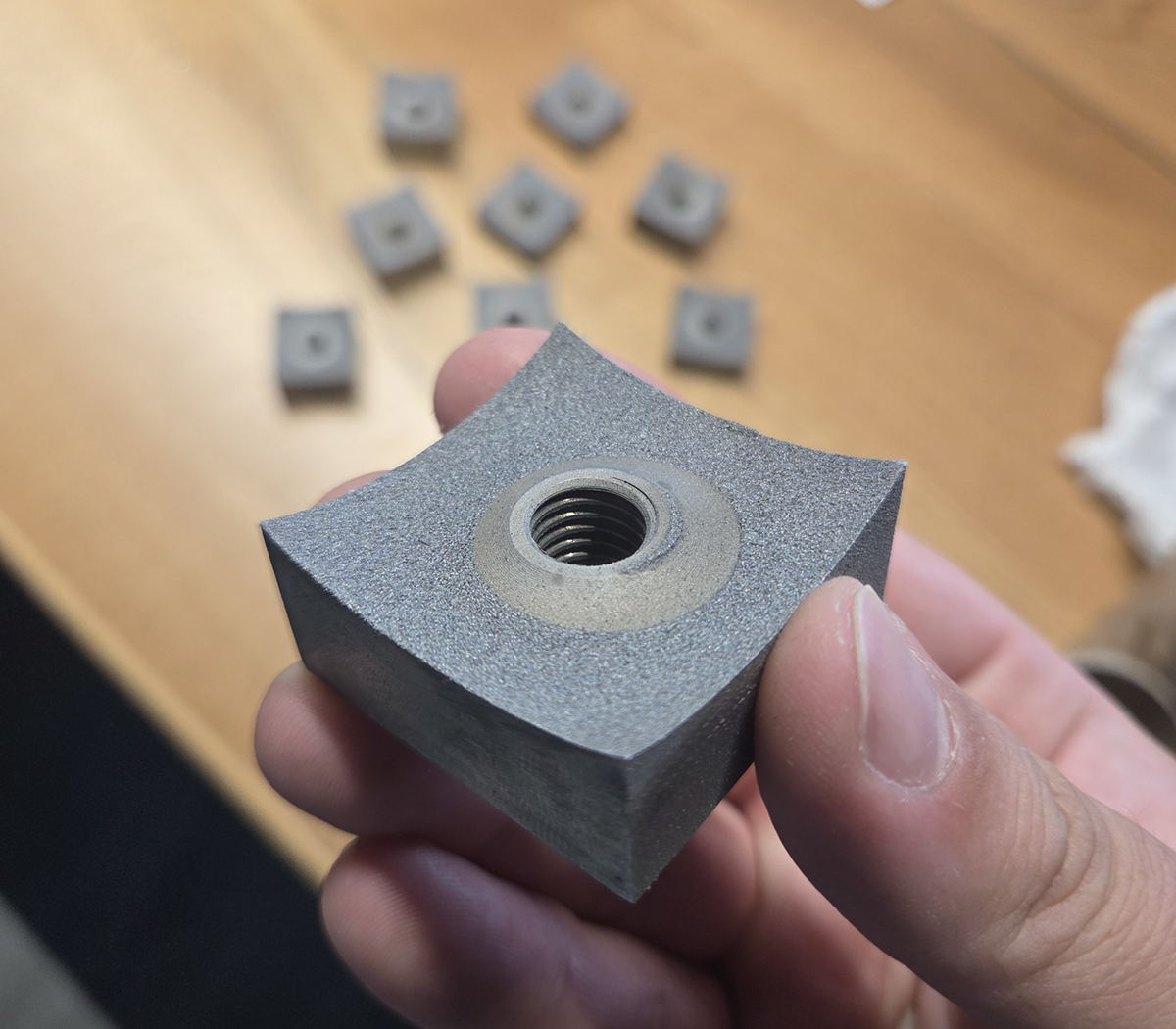

This project focuses on metallizing industrial knives for Amis Recycling Technology SHREDDER and GRANULATOR to improve durability and reduce maintenance costs.

Using advanced metallization techniques and both commercial and proprietary recycled superalloy powders, it extends knife lifespan while promoting circular economy principles. The project aims for TRL6+ demonstration and market-ready sustainable recycling solutions that lower environmental impact and operational costs.

Industrial shredders and granulators are at the heart of modern recycling processes, yet their knives face extremely demanding operating conditions. High impact forces, abrasive and adhesive wear, and friction-induced temperature increases often lead to rapid tool degradation, frequent replacements, and costly downtime. These challenges reduce plant efficiency and increase the environmental footprint of recycling operations.

The MOIK project (Metallization of Industrial Knives), funded under the INCIRCULAR programme, directly addresses these issues. The project develops and validates advanced metallization techniques to significantly improve the durability and performance of knives used in Amis Recycling Technology’s SHREDDER and GRANULATOR systems.

The innovative approach combines:

High-performance commercial alloys with proven industrial reliability, and

Proprietary powders recovered from valuable superalloy dust generated during grinding processes.

This dual-powder feedstock strategy enables the creation of coatings with superior hardness, fracture toughness, adhesion, and resistance to wear and corrosion compared to conventional steels. Early industrial tests confirm that metallized knives achieve extended operational lifetimes, reduced maintenance requirements, and lower overall operating costs.

Beyond technical benefits, MOIK contributes to circular economy principles by valorizing secondary raw materials, improving resource efficiency, and reducing waste. The project not only provides direct savings for recycling operators but also demonstrates how advanced surface engineering can align with environmental and sustainability goals.

The project is implemented by Ekstera d.o.o. and Additio d.o.o., in collaboration with Amis Recycling Technology GmbH, within the framework of INCIRCULAR. Together, the partners are working towards TRL6+ demonstration and near-market deployment, positioning metallization as a scalable, sustainable, and economically viable innovation for the recycling industry.

About the company

Ekstera is a pioneering company dedicated to advancing sustainability and the circular economy. Specialising in the research and processing of secondary raw materials, metal recycling, and industrial symbiosis, Ekstera transforms waste into valuable resources while helping businesses optimise waste management and reduce their environmental footprint.

With a strong commitment to innovation, the company develops cutting-edge materials and manufactures high-performance industrial knives for recycling applications. Its product portfolio includes the MATTERRA cup, a biodegradable and reusable solution designed to minimise single-use plastic waste. Additionally, Ekstera provides sustainable transportation services, ensuring efficient and responsible material logistics.

“This project has received funding from the European Union within the framework of the IN CIRCULAR Project funded under grant agreement No 101114988”.